Release Date:2022-09-05 09:48:46

share

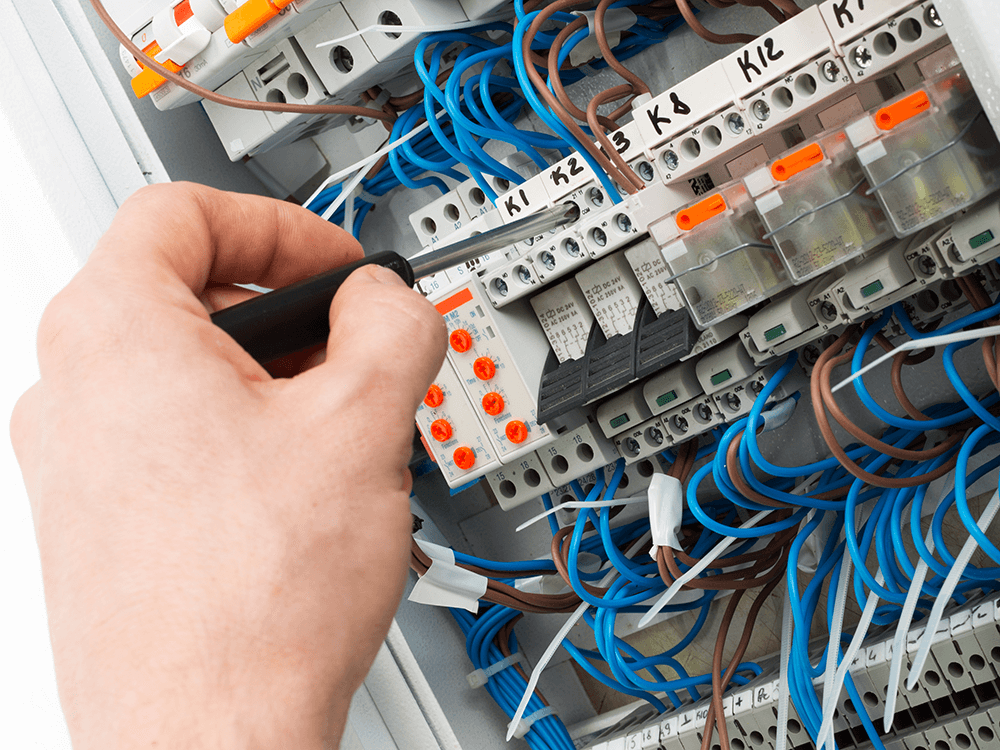

In order to make the circuit breaker operate more freely, we should not neglect its maintenance. If you maintain it regularly, its life will be many times longer. Why not? In order to keep it in good working condition, maintenance needs to be constantly strengthened. So, what are the main points of its maintenance? In terms of maintenance, we should keep the air fresh. If the air is wet or not clean, the consequences are very serious. The wet gas is decomposed into hydrogen and oxygen mixed gas, which will cause thermal insulation after fracture between contact points, and even cause explosion of electric room in serious cases. It will make the insulation strength lower, and the surface will gradually discharge, which will prevent you from melting. In case of electricity, the consequences can be imagined, so it is better to be careful. In addition, the pipeline will be blocked when painting, and the circuit will fail or even be stuck. These are all caused by unclean air, which is very different. Therefore, we should always keep the air clean. Rubber parts are one of the important items, and rubber inspection parts should be replaced regularly, because the structure of this device is very complex and the sealing requirement is high. In order to ensure its performance, it is necessary to replace rubber parts in time. All parts of the air switch need to be checked regularly to keep them in a good technical condition. Don't ignore a small device, which may determine the normal operation of the device. For example, the chamber needs to regularly check its springs, dynamic and static corner contacts. Because of its constant friction, the outlet overtravel will slowly reduce the pressure. When it is small enough, the spring will deform. At that time, it should be replaced in a timely manner. The non-linear resistance needs to be checked for cleanliness, the desiccant inside should be replaced, and the non-linear resistance should be measured. Check the size of the piston and valve body of the main valve to see if its size is within the specified range. If not, correct it in time. The drive cylinder also needs to be checked. Adjust its buffer zone, ensure its disconnecting switch, and timely check its accuracy. Also, maintain its performance better through maintenance and replacement. For the daily maintenance of circuit breakers, we only need to do the above points, and I believe it will have a great effect. It is very important to ensure that the air in the environment where it is used is fresh, timely replacement of rubber parts, inspection of small parts, etc. It only takes you a little time to reduce the trouble of the device, and the maintenance of the device should start from the small things in life, which cannot be ignored.